A detailed, step-by-step, guide to diagnosing and correcting common configuration errors in CO₂ injection, lighting control, solution dilution, pH adjustment, nutrient mixing, and irrigation scheduling—so your climate-controlled hydroponics delivers peak yields.

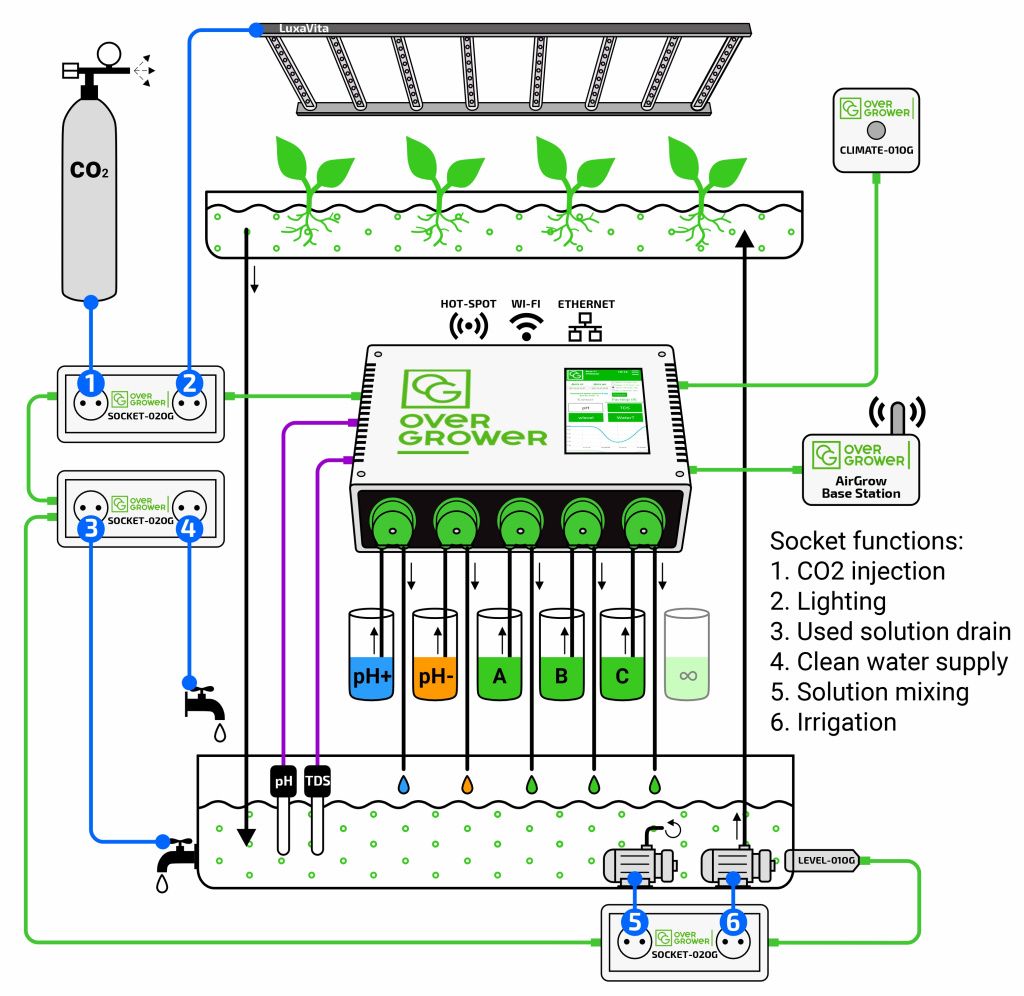

Modern home hydroponic setups like the OverGrower controller above promise turnkey precision—automated CO₂ dosing, scheduled lighting, self-mixing reservoirs, pH regulation, multi-channel nutrient delivery, level sensing, and pump-driven irrigation. Yet even a well-engineered platform can underperform if one or more of its six socket functions (CO₂, lighting, drain, supply, mixing, irrigation) are mis-configured. In this seven-phase guide, we’ll walk through each subsystem, identify the top mistakes, and show you exactly how to correct them—ensuring balanced root zones, stable chemistry, and vigorous plant growth.

Phase 1: Correcting CO₂ Injection Timing and Dosage (Socket 1)

Common Mistake: Injecting CO₂ continuously or at night, causing waste and potential plant stress.

- Determine Optimal CO₂ Setpoint:

- Most leafy greens and herbs thrive at 1,000–1,200 ppm during photosynthesis. Set your OverGrower “CLIMATE-010G” sensor to maintain 1,050 ppm as the upper limit, with a lower threshold of 800 ppm before dosing resumes.

- Schedule Daytime-Only Injection:

- Program socket 1 for CO₂ to run only during the “lights-on” period. For an 18 h photoperiod, configure injection from hour 0 to hour 18 in your OverGrower interface.

- Calibrate Flow and Check Dispersion:

- Install the CO₂ diffuser at midpoint of the grow tray to ensure even distribution.

- Use a handheld CO₂ monitor at plant canopy height to confirm ±5 % of setpoint across the entire bed.

Phase 2: Refining Lighting Control (Socket 2)

Common Mistake: Mismatched photoperiods, insufficient intensity, or forgetting night-time blackout.

- Set Accurate Photoperiod:

- For vegetative growth, run lights 18 h on / 6 h off; for finishing, switch to 12 h on / 12 h off.

- In the OverGrower schedule for socket 2, program your LuxaVita LED bar to exactly these intervals—double-check AM/PM boundaries to avoid forced dark interruptions.

- Verify Light Intensity:

- Measure PPFD at canopy level with a PAR meter. Aim for 200–300 µmol/m²/s for leafy greens, 400 µmol/m²/s for fruiting herbs.

- Adjust the LED bar height or dimming control in the OverGrower UI until readings fall within target ranges.

- Implement Soft-Start Dimming:

- Configure the OverGrower’s dimming curve to ramp up over 5 minutes at “lights on” and ramp down at “lights off.” This reduces stress on plants and LEDs.

Phase 3: Automating Reservoir Drain and Refill (Sockets 3 & 4)

Common Mistake: Draining too frequently or refilling with cold water—shocking roots and destabilizing pH.

- Optimize Drain Frequency (Socket 3):

- Excessive draining (e.g., every 2 h) can strip beneficial microbes. Set your “used-solution drain” to once per 24 h, ideally in the early morning subjective minute, to prevent root oxygen deprivation.

- Control Water Supply Temperature (Socket 4):

- Program the clean-water inlet pump to fill only when the reservoir temperature sensor reads within 2 °C of the current solution. Install a small in-line heater/chiller if necessary.

- Level Sensor Calibration:

- With “LEVEL-010G” in place, run the OverGrower’s auto-calibration routine: fill to maximum mark, zero the top threshold; drain to minimum mark, zero the bottom threshold. This prevents overfill spills or dry runs.

Phase 4: Precision pH Management (pH+ and pH– Lines)

Common Mistake: Over-titration or sluggish correction due to incorrect dosing order.

- Titrate with Small Increments:

- Configure the pH+ (purple line) and pH– (orange line) peristaltic pumps to dispense in 1 mL pulses with 30 s interval, rather than large single dumps. This avoids overshooting your 5.8–6.2 target.

- Order of Operations:

- Always add pH adjustments before nutrients. In your mixing routine, program the OverGrower to:

- Drain 10 % of reservoir (socket 3).

- Refill 5 % with clean water (socket 4).

- Add pH corrections in 1 mL increments until the sensor stabilizes.

- Then dispense A, B, C nutrients as outlined below.

- Always add pH adjustments before nutrients. In your mixing routine, program the OverGrower to:

- Sensor Maintenance:

- Weekly, remove and soak your pH probe in phosphate storage solution. Perform a two-point calibration (pH 4.00 and 7.00 buffers) using the OverGrower’s calibration menu.

Phase 5: Balancing Three-Part Nutrient Delivery (Lines A, B, C)

Common Mistake: Incorrect A:B:C ratios or mixing order—leading to nutrient lockout or precipitation.

- Follow Manufacturer Ratios:

- Use the bottle labels: e.g., 3 mL of A, 3 mL of B, and 2 mL of C per liter of solution for vegetative stage. Program the OverGrower’s dosing schedule to match these exact volumes each cycle.

- Sequence to Prevent Precipitates:

- In your mixing routine, set the order:

- Add Bottle A (calcium‐and‐magnesium source).

- Wait 10 s mixing (socket 5 engages mixing pump).

- Add Bottle B (primary NPK).

- Wait 10 s mixing.

- Add Bottle C (micronutrient chelates).

- Final 30 s mixing before irrigation.

- In your mixing routine, set the order:

- Auto-Flush Between Formulas:

- If you switch from veg to bloom formula, program an auto-flush of 20 % reservoir volume and refill with plain water before adding new A/B/C ratios—avoiding cross‐contamination.

Phase 6: Streamlining Irrigation and Root-Zone Delivery (Socket 6)

Common Mistake: Insufficient run time or poor distribution—hot spots and dry roots.

- Calculate Optimal Irrigation Cycle:

- For ebb-and-flow, design a 10 min flood, 50 min drain cycle for young plants; shift to 15 min flood, 45 min drain for mature crops.

- Program socket 6 to power the irrigation pump accordingly.

- Ensure Uniform Drip Lines:

- Use a manifold or equally-spaced drip emitters across the tray. Before powering up, test each emitter in a bucket—confirm 200 mL/min output ±5 %.

- Install a Pressure Regulator:

- Keep line pressure at 10–15 psi to prevent misting or pulsation. Strong, steady drips help roots avoid anaerobic pockets.

Phase 7: Final Checks, Data Logging, and Remote Alerts

- End-to-End Functional Test:

- Run a full 24-h cycle in “dry-run” mode: simulate all phases (CO₂ injection, lights on/off, drain/refill, pH correction, nutrient dosing, irrigation). Inspect physical responses: solenoid clicks, pump flow, LED dimming.

- Data-Log and Trend Analysis:

- Enable OverGrower’s built-in Hot-Spot, Wi-Fi, or Ethernet connectivity to stream sensor data to the cloud. Review graphs weekly:

- CO₂ stability curve (should hover within ±50 ppm).

- pH and EC trends (±0.1 unit over 24 h).

- Solution level consistency and irrigation pump runtimes.

- Enable OverGrower’s built-in Hot-Spot, Wi-Fi, or Ethernet connectivity to stream sensor data to the cloud. Review graphs weekly:

- Set Remote Alerts:

- Create SMS or email alerts for any of:

- CO₂ >1,300 ppm or <700 ppm

- pH out of 5.7–6.3 range

- Tank level <20 %

- Temperature >28 °C (risk of stress)

- Disconnected sensors or power interruptions.

- Create SMS or email alerts for any of:

Conclusion

By systematically optimizing each OverGrower socket—from CO₂ injection and lighting schedules through reservoir management, pH titration, nutrient sequencing, and irrigation control—and by layering in robust calibration, logging, and alerting, you’ll eliminate the six most common pitfalls that hold back home hydroponic growers. The result is a truly hands-off, precision-tuned ecosystem: roots bathed in perfectly balanced solution, canopies fed the exact light and CO₂ they demand, and harvests that rival the pros—no greenhouse required.