By Architectural Digest: Build Edition | August 5, 2025

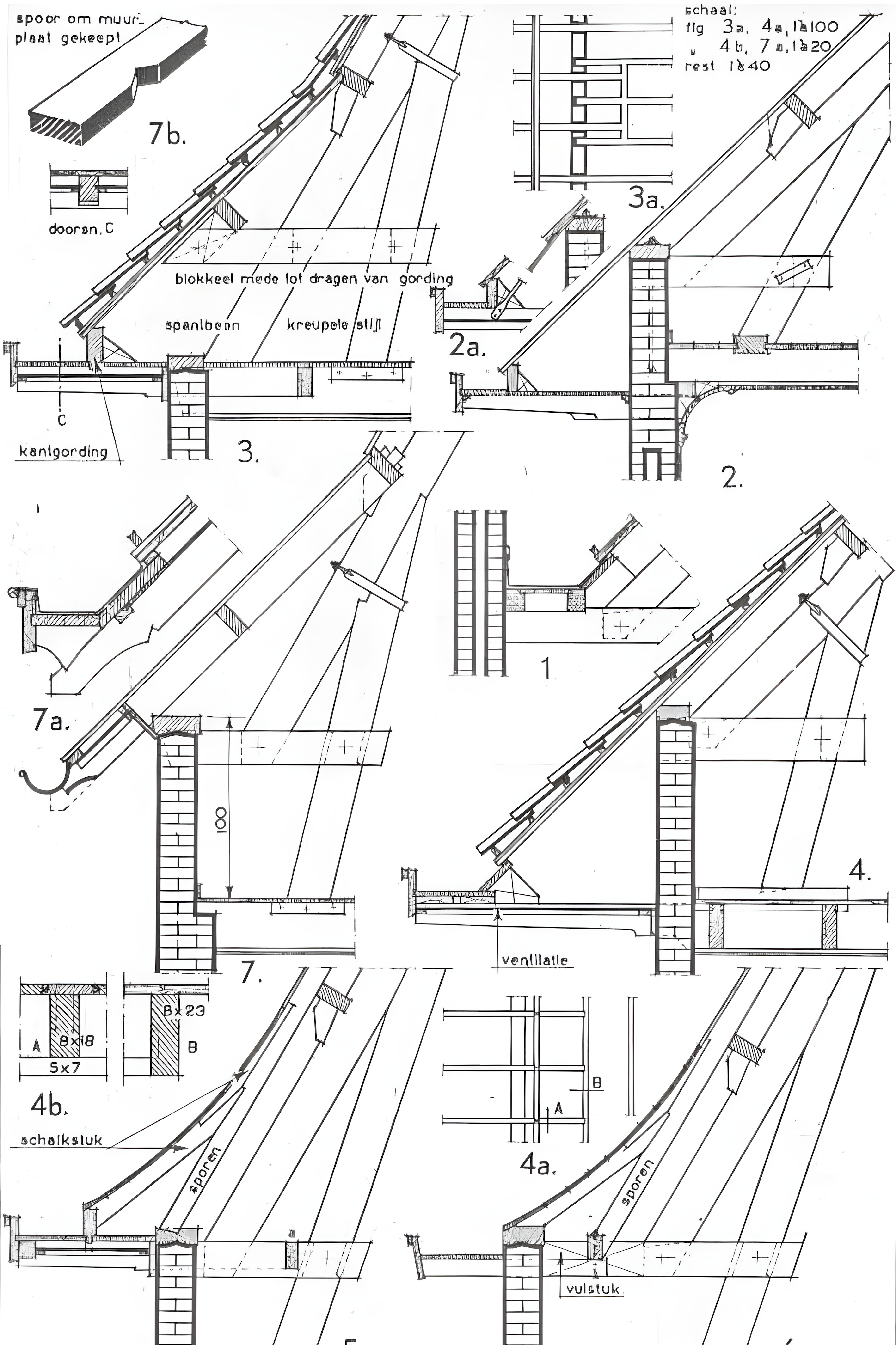

When it comes to timber-framed buildings, the cornice—the transition between wall and roof—can make or break both performance and style. A well-executed cornice manages rainwater, ventilates attic space, and delivers a crisp architectural finish. The vintage diagram above, titled “A Dozen Simple Cornices for Frame Buildings”, showcases nine time-tested profiles, each numbered for easy reference. In this detailed, news-style walkthrough, we’ll transform these inked drawings into on-site realities. Whether you’re renovating a craftsman bungalow or erecting a new garden studio, you’ll learn exactly how to select and build the cornice that fits your frame.

Why Cornices Matter

- Weather Protection

A properly angled drip edge prevents water from tracking back under roofing materials or dripping onto siding, which avoids rot and leaks. - Ventilation

Many cornices incorporate soffit vents or open gaps to feed attic airflow, guarding against moisture buildup and heat-soak in summer. - Load Transfer

Rafter tails and fascia boards must be securely fastened to carry wind uplift loads and snow weight down into the wall studs. - Aesthetic Finish

From simple drip edges to decorative brackets and moldings, cornice details define a building’s character.

Cornice 1: The “Molded Eave” (Detail 1)

Features:

- 2×4 rafter tails

- Fascia trimmed with a 2″×4″ crown molding

- Painted metal drip gutter tucked behind shingles

How to Build:

- Rafter Preparation

- Cut the rafter tails flush at the correct overhang length (typically 12″–18″).

- Plane a 10° slope on the underside so water sheds cleanly.

- Install the Crown Molding

- Choose a rot-resistant wood (cedar or cypress).

- Pre-paint both faces for longevity.

- Fasten the molding to the fascia board with stainless steel finish nails, aligning its profile to match the roof pitch.

- Fit the Drip Gutter

- Slip the gutter flange between the roofing felt and the bottom course of shingles.

- Secure with roofing cement and small copper nails.

- Seal the top lip under the felt apron.

Cornice 2: The “Boxed Eave with Soffit” (Detail 2)

Features:

- Enclosed soffit beneath 2″×4″ rafters

- 1″×5″ fascia board

- Continuous G.I. or aluminum gutter

How to Build:

- Ledger and Soffit Framing

- Attach a 2″×4″ ledger board to the wall stud tops, secured with ½″ lag screws at 16″ on center.

- Run 2″×4″ joist hangers from the ledger, fastening matching soffit joists perpendicular to the rafters.

- Install Soffit Panels

- Use pre-vented vinyl soffit panels or tongue-and-groove cedar.

- Leave a ¾″ gap at the wall plate for intake ventilation.

- Fascia and Gutter

- Fix a 1″×5″ fascia to the rafter tails, covering the soffit edges.

- Mount the gutter flange directly to the fascia, ensuring a fall of ¼″ per 10′ run.

Cornice 3: The “Open Rafters with Drip Edge” (Detail 3)

Features:

- Exposed rafter tails

- 2″×6″ thick fascia matched flush with rafter bottom

- Slim metal drip flashing

How to Build:

- Rafter Tail Finishing

- Round-over or chamfer rafter tail ends for a refined look.

- Smooth with 120-grit sandpaper, then prime and paint.

- Attach Drip Flashing

- Bend 26-gauge galvanized steel into an L-shape with a rolled nose.

- Slip the upper leg under the felt, nail through the roofing, and fold the lower leg over the rafter tail.

- Fascia Installation

- Scribe the 2″×6″ fascia against the wall sheathing.

- Secure with exterior-grade wood screws, countersunk and filled.

Cornice 4: The “Bracketed Eave” (Detail 4)

Features:

- 2″×8″ joists Cantilevered 8″ beyond wall face

- Decorative 1″×6″ wood brackets

- Gutter strapped to the bracket bottom

How to Build:

- Cantilever Joist Layout

- After placing joist hangers at the wall line, slip each 2″×8″ joist into position and toe-nail it through the ledger.

- Cut and Fit Brackets

- Trace a bracket pattern (6″ projection with a 2″ rise) on 1″×6″ stock.

- Bandsaw the curves, sand edges, and fish-mouth to seat the joist bottoms.

- Gutter Attachment

- Bolt 2″ gutter straps through the bracket bottoms.

- Use sealant at every bolt penetration.

Cornice 5: The “Splayed Soffit” (Detail 5)

Features:

- Soffit board sloping down at 10° from horizontal

- 2″×4″ rafter tails set back 2″ from the fascia face

- Small crown molding at the lower soffit edge

How to Build:

- Rafter Tail Setback

- Mark each tail 2″ in from its clipped end.

- Cut a short vertical face there so the fascia can mount flush.

- Soffit Boarding

- Rip 1″×8″ boards at a 10° bevel on one edge.

- Screw them to rafter tails and ledger. Maintain 1/16″ gap at seams for expansion.

- Finish with Molding

- Nail a ½″×3″ ogee molding to the soffit’s lowest edge for a shadow line.

Cornice 6: The “Deep Recessed Soffit” (Detail 6)

Features:

- 2″×10″ joists with 2″×4″ rafter tails

- Soffit dropped 6″ below joist bottom

- 2″×2″ open slot vents every 24″

How to Build:

- Rafter & Joist Coordination

- Stub the rafter tails into a 2″×10″ beam using 8″ timber screws.

- Double-check alignment so the soffit plane sits level.

- Soffit Framing

- Erect soffit furring strips perpendicular to joists, set 6″ down.

- Leave 2″×2″ openings between every two strips for venting.

- Install Soffit Panels

- Nail ¼″ plywood or fiber cement board to the furring.

- Lace the vents with insect mesh.

Cornice 7: The “Tin-Roof Eave” (Detail 7)

Features:

- 2″×6″ rafters under tin roof panels

- Extended 2″×4″ drip edge folded in tin

- Exposed rafter ends painted to match

How to Build:

- Rafter Prep & Paint

- Shape the tail profile with a ½″ round-over bit.

- Prime and finish with two coats of exterior enamel.

- Drip Edge Integration

- After laying the tin panels, fold the last 2″ of sheeting over a 2″×4″ drip board.

- Secure with factory recommended clips.

- Seal Terminations

- Apply a non-hardening butyl sealant along the folded edge.

- Rivet every 12″ with neoprene-gasketed rivets.

Cornice 8: The “Reverse Falcorso” (Detail 8)

Features:

- Roof boards carried past rafters, underside finished with a 2″×6″ fascia

- Vertical 2″×4″ strut tying boards back to wall plate

- Simple drip into a half-round gutter

How to Build:

- Extend Roof Sheathing

- Nail the roof boards (¾″ plywood) to extend 2″ beyond rafter tails.

- Counterbore and fill nail holes.

- Strut Installation

- Cut 2″×4″ struts at the correct bevel to connect the board lip back to the wall plate.

- Bolt through with carriage bolts and washers.

- Fascia and Gutter

- Pin a half-round gutter flange to the board undersides.

- Cap the fascia with drip flashing for a clean reveal.

Cornice 9: The “Minimalist Braced Eave” (Detail 9)

Features:

- 2″×4″ braces at 45° between rafter and fascia

- 1″×10″ fascia board

- Gutter recessed behind the board face

How to Build:

- Brace Fabrication

- Rip 2″×4″ braces on a table saw to achieve the correct cross-section for both faces.

- Fasten with structural screws at top and bottom.

- Fascia Hanging

- Screw the 1″×10″ fascia to the rafter ends, hiding screw heads in the bottom third.

- Pre-drill every fixing to avoid splitting.

- Recessed Gutter Fit

- Sink the gutter trough behind the fascia board, mounted on concealed brackets.

- Ensure the fascia face covers the gutter lip by 1″ to shield it from view.

Final Tips for All Cornices

- Use Corrosion-Resistant Fasteners: Stainless steel or hot-dip galvanised for all exterior timber and flashing attachments.

- Test Slope and Drainage: Before cladding, mist-spray the eaves with a hose to ensure water sheds properly.

- Prime and Paint: Seal all end grains, cut edges, and fastener holes before installation to prevent moisture ingress.

- Maintain Clearances: Leave 1/8″ expansion gaps at wood-to-wood joints; fill with matching exterior sealant after assembly.

By following these nine step-by-step instructions, you’ll not only secure your roof against wind and rain but also craft a distinctive cornice profile that complements your building’s style. From simple drip edges to ornate bracketed eaves, these classic frame-building details continue to stand the test of time—combining durability, ventilation, and the timeless grace of a well-resolved roofline.