A step-by-step, guide to diagnosing and correcting design and installation errors— from panel oversizing and missing MPPT controllers to insufficient piping and lack of storage—so your solar-powered pump delivers consistent, energy-efficient water flow year-round.

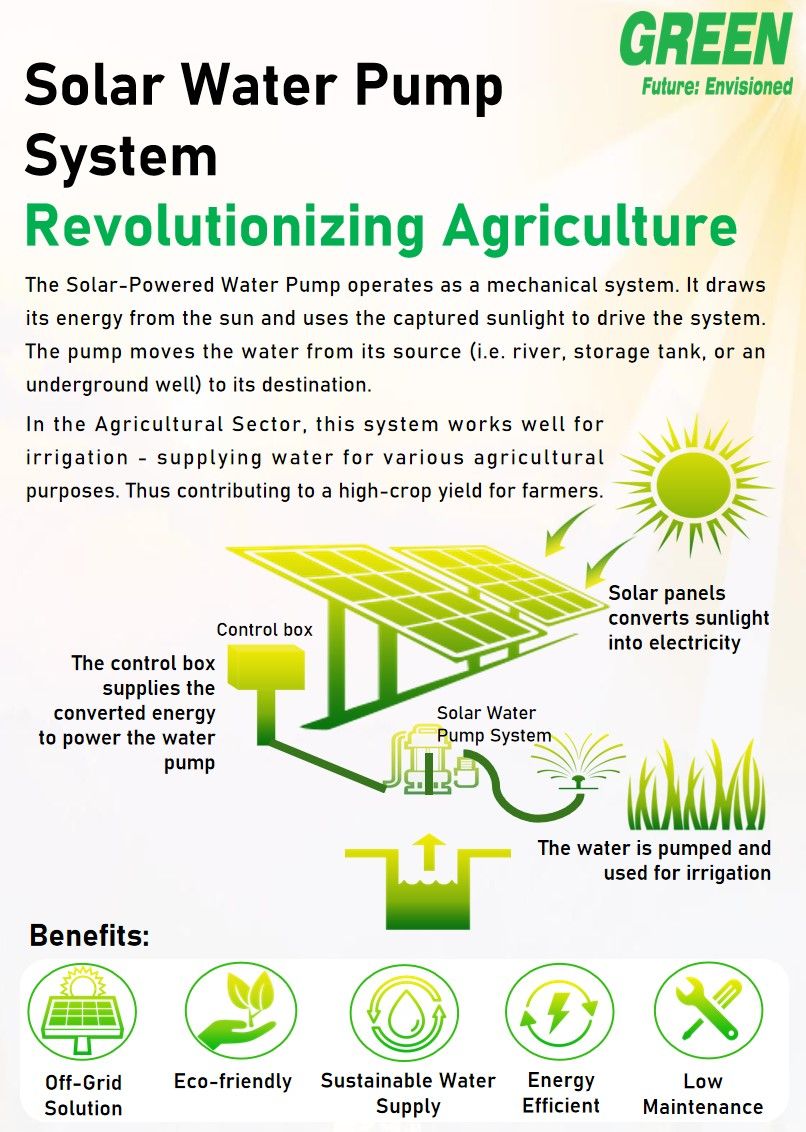

In the quest for sustainable agriculture and off-grid living, solar-driven water pumps promise an eco-friendly solution—yet far too many installations falter due to one or more avoidable mistakes. Panels go un-matched to pump requirements, controllers are omitted or mis-configured, intake and delivery piping chokes flow, and lack of storage leaves farmers stranded when clouds roll in. In this in-depth guide, we’ll walk through each critical component of a solar water pump system, identify the most common missteps, and provide a clear, seven-phase correction plan to optimize performance, ensure reliability, and maximize crop yields.

Phase 1: Right-Sizing Your Solar Array

Mistake: Installing an undersized or oversized panel array leads to poor pump operation or wasted investment.

- Calculate Pump Power Needs:

- Obtain the pump’s wattage rating at its operating point (flow rate and head).

- Example: A 1,500 W pump drawing 12 A at 120 VAC.

- Determine Peak Sun Hours:

- Use local solar insolation data: e.g., 5 peak sun hours/day.

- Compute Required Array Size:

- Required daily watt-hours = pump wattage × run hours.

- If you run 6 hours/day: 1,500 W × 6 h = 9,000 Wh.

- Panel array = 9,000 Wh / 5 h = 1,800 W.

- Include 20 % system losses: 1,800 W × 1.2 ≈ 2,160 W total.

- Select Panel Configuration:

- Use 12 panels × 200 W each = 2,400 W. Wire in series/parallel to match pump voltage and controller input.

Phase 2: Choosing and Configuring the Controller

Mistake: Omitting a Maximum Power Point Tracking (MPPT) controller or using a simple PWM device—resulting in up to 30 % power loss.

- Why MPPT Matters:

- It continuously adjusts voltage/current to extract maximum power from panels as irradiance and temperature change.

- Sizing the Controller:

- Voltage rating ≥ open-circuit voltage (Voc) of panel string.

- Current rating ≥ short-circuit current (Isc) × 1.25.

- Wiring and Settings:

- Connect panels to MPPT input.

- Set the controller’s output voltage to match pump motor specifications (e.g., 48 V DC).

- Enable any built-in safety timers or low-voltage shutdown to protect the pump.

Phase 3: Streamlining Intake and Delivery Piping

Mistake: Undersized, overly long, or poorly anchored pipes causing excessive friction losses and airlocks.

- Calculate Optimal Pipe Diameter:

- Aim for pipe velocity of 3–5 ft/s.

- Example: For 10 gpm pump, Q = 0.022 cfs. Required area = Q/velocity ≈ 0.0044 ft² → diameter ≈ 2.5″. Use 2″ minimum.

- Minimize Length and Fittings:

- Keep suction and discharge runs as short and straight as possible.

- Use gradual fittings (sweeps) instead of sharp elbows to reduce turbulence.

- Prevent Airlocks:

- Install automatic foot-valve with quality strainer at intake.

- Prime lines and include a bleeder valve at the highest point.

- Anchoring and Support:

- Secure pipes every 3–5 ft with clamps to prevent vibration and sag.

Phase 4: Integrating Adequate Storage

Mistake: Relying solely on real-time pumping—leaving no buffer for cloudy days or peak demand.

- Sizing Your Storage Tank:

- Determine daily irrigation requirement (e.g., 5,000 L/day).

- Provide at least 1–2 days of storage: 10,000 L tank.

- Tank Placement and Height:

- For gravity feed, mount tanks on towers to achieve desired pressure (0.1 bar per meter).

- A 5 m elevation gives ~0.5 bar (~7 psi).

- Float Switch Automation:

- Install high/low float switches to start the pump when tank level falls below set point and shut off when full.

Phase 5: Electrical Safety and Grounding

Mistake: Skimping on conduits, using non-DC rated wiring, and neglecting grounding—creating electrocution and fire hazards.

- Wire Selection:

- Use UV-resistant, PV-rated cables for panel runs.

- For pump leads, choose marine-grade, direct burial DC cable sized for <3 % voltage drop.

- Conduit and Junction Boxes:

- Run all DC wiring in UV-protected conduit.

- Weatherproof, lockable junction boxes with proper strain relief.

- Grounding and Lightning Protection:

- Bond panel frames and controller chassis to a grounding electrode system.

- Consider DC surge arrestors and AC surge protectors for controller output.

Phase 6: Routine Maintenance and Monitoring

Mistake: Installing and forgetting—leading to dirty panels, fouled intakes, and undetected faults.

- Panel Cleaning Schedule:

- Wash panels with soft brush and de-ionized water monthly or after dust storms.

- Filter and Strainer Checks:

- Inspect foot-valve strainer weekly during irrigation season. Clean out debris to maintain flow.

- Controller and Pump Logs:

- Record daily run times, voltages, and flow rates.

- Flag any drop in performance (e.g., 10 % less flow than baseline) for inspection.

Phase 7: Troubleshooting Common Issues

- Low Flow Despite Full Sun:

- Check for air leaks in suction line, blocked strainer, or closed valves.

- Verify MPPT controller is tracking correctly—look for “MPP” indication.

- Pump Cycling On/Off Rapidly:

- Likely float switch mis-adjustment or wiring fault.

- Inspect switch heights and cable continuity.

- Panels Overheating or Controller Shutting Down:

- Ensure adequate ventilation around the controller.

- Verify wiring torque on terminals and clean any corrosion.

- System Yields Less in Winter:

- Accept seasonal performance drop.

- For critical irrigation, plan supplemental power (wind, backup generator, or grid-tie inverter).

Conclusion

By following this seven-phase correction plan—right-sizing panels, installing an MPPT controller, optimizing piping, adding proper storage, enforcing electrical safety, committing to regular maintenance, and knowing how to troubleshoot—you’ll transform a temperamental solar water pump into a robust, low-maintenance powerhouse. Whether you’re irrigating a small market garden or supplying a remote homestead, these best practices ensure your off-grid system harnesses every ray of sun to deliver reliable, energy-efficient water flow throughout the seasons.